Industrial Equipment Repair

Operating and maintaining manufacturing

equipment already comes with some known costs, but unexpected equipment

failures can increase those costs exponentially, especially when you

cannot see where the failure occurred or where it is located. This is

often the case with drag chain conveyors used in a manufacturing

process that requires those conveyors to be fully enclosed to prevent

dust and fumes (fugitive emissions) from escaping into the environment.

When a

fully enclosed drag chain conveyor breaks down, and a repair is

required to get it back running again, the covers must be removed to

locate the problem. These conveyors move stuff between point A and

point B, those points may be hundreds of feet away and 100 feet above

the ground, further complicating the repair process. To access the

covers, one or more man-lifts must be used to lift repair technicians

and their tools. A crane is then needed to lift off and lower each

cover safely to the ground. The covers are removed until the area that

caused the breakdown is discovered or when there are no more covers to

be removed.

When a

fully enclosed drag chain conveyor breaks down, and a repair is

required to get it back running again, the covers must be removed to

locate the problem. These conveyors move stuff between point A and

point B, those points may be hundreds of feet away and 100 feet above

the ground, further complicating the repair process. To access the

covers, one or more man-lifts must be used to lift repair technicians

and their tools. A crane is then needed to lift off and lower each

cover safely to the ground. The covers are removed until the area that

caused the breakdown is discovered or when there are no more covers to

be removed.

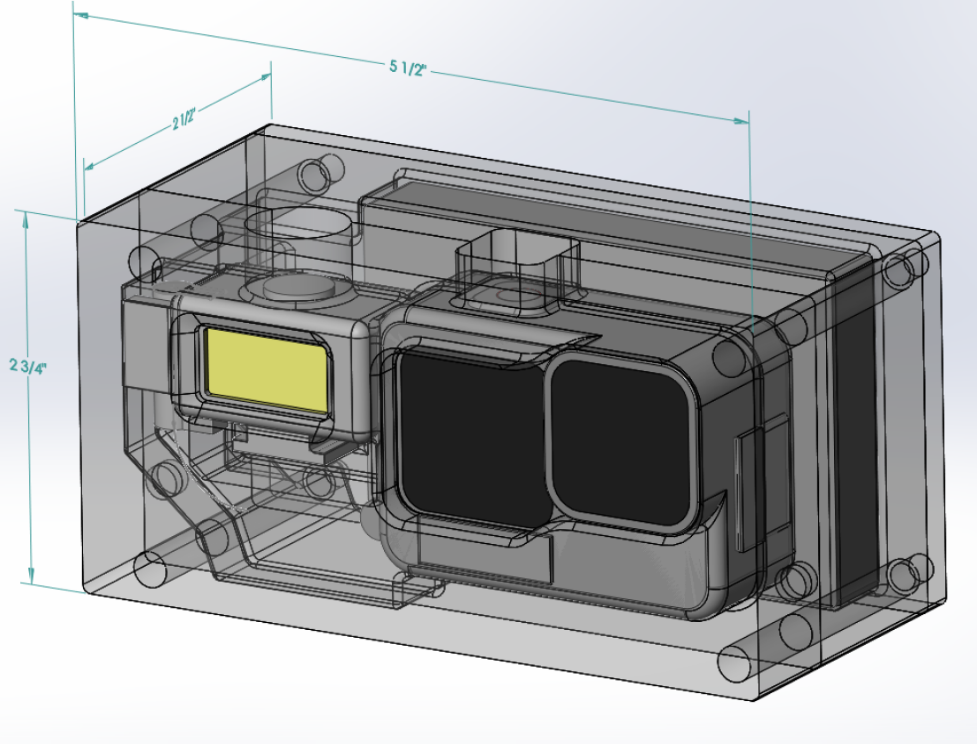

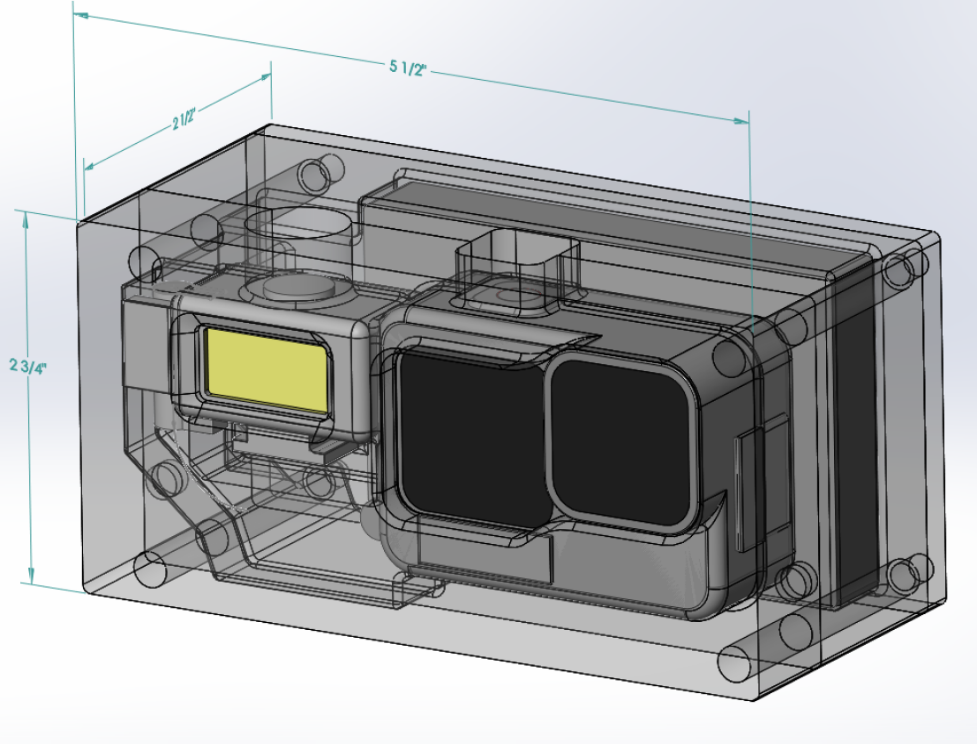

To

reduce these costs, we developed a device that allows a camera to be

placed directly inside the conveyor where it can ride along on the drag

chain and take a video of the conveyor's entire internal surface area,

including structural supports and drive components. This video can then

be analyzed to determine the cause of the problem and where it is

located, allowing repair efforts and resources to be solely focused on

the problem, not wasting time risking injuries searching for the

problem.

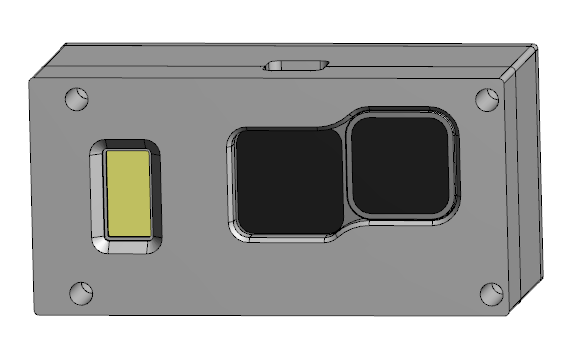

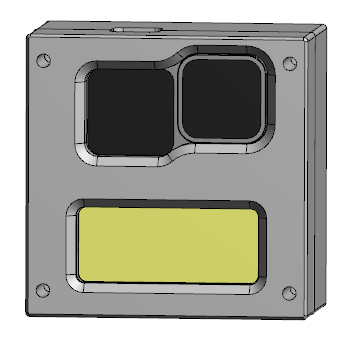

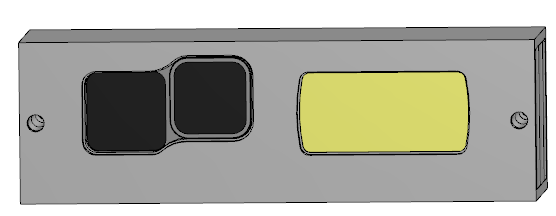

This

inspection device helps protect the camera, lighting, and other related

electronics from damage, and provides alternative ways to be secured to

the chain in a drag chain conveyor, which include magnets, screws,

steel cable, etc. To ensure the camera can see the problem we are

searching for, it is accompanied with an L.E.D light that illuminates

all the otherwise dark internals of the conveyor. An auxiliary battery

can also be placed inside to power both the camera and light to

increase the recording time.

Contact

us with any questions or to explore our inspection devices:

630-465-8859

Plainfield, IL, USA

info@itsees.com

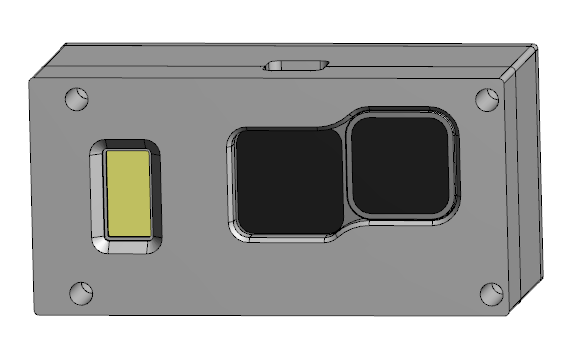

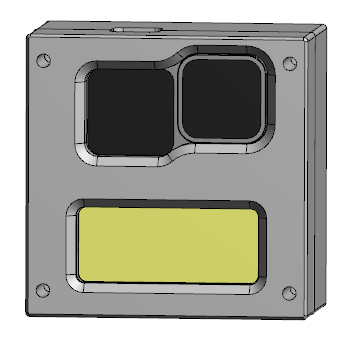

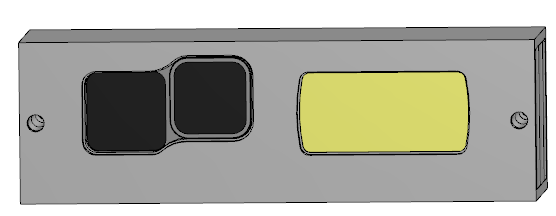

Here

are some examples of the devices we provide:

When a

fully enclosed drag chain conveyor breaks down, and a repair is

required to get it back running again, the covers must be removed to

locate the problem. These conveyors move stuff between point A and

point B, those points may be hundreds of feet away and 100 feet above

the ground, further complicating the repair process. To access the

covers, one or more man-lifts must be used to lift repair technicians

and their tools. A crane is then needed to lift off and lower each

cover safely to the ground. The covers are removed until the area that

caused the breakdown is discovered or when there are no more covers to

be removed.

When a

fully enclosed drag chain conveyor breaks down, and a repair is

required to get it back running again, the covers must be removed to

locate the problem. These conveyors move stuff between point A and

point B, those points may be hundreds of feet away and 100 feet above

the ground, further complicating the repair process. To access the

covers, one or more man-lifts must be used to lift repair technicians

and their tools. A crane is then needed to lift off and lower each

cover safely to the ground. The covers are removed until the area that

caused the breakdown is discovered or when there are no more covers to

be removed.